Digital Board Replacement

TANK PRESSURE INDICATOR KIT

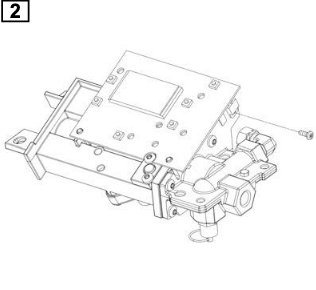

165-0267 - Manual regulator control

CAUTION: To prevent damage to the programmed control board, static grounding must be worn during handling and assembly.

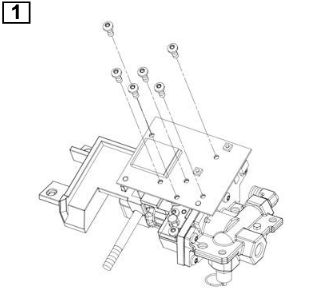

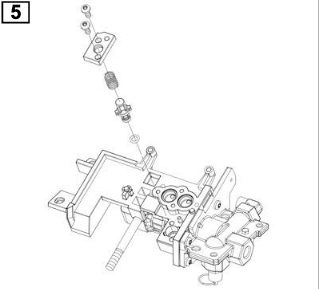

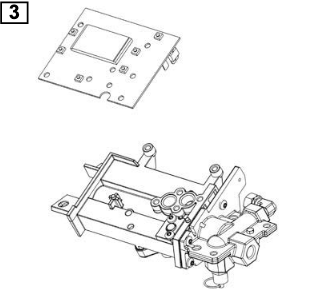

Remove 6 control board screws.

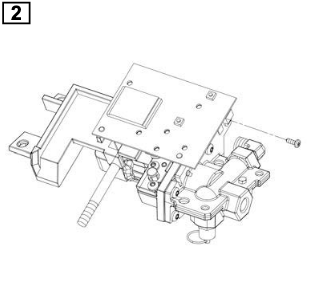

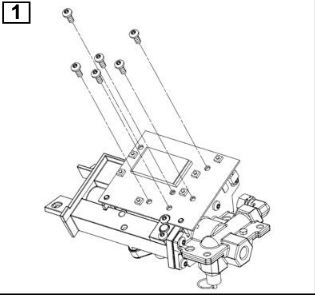

Remove triac screw.

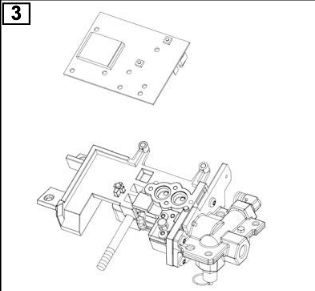

Lift the control board from the manifold.

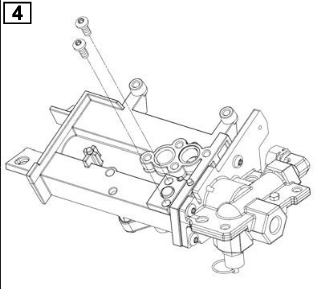

Remove the 2 screws from the tank indicator cap.

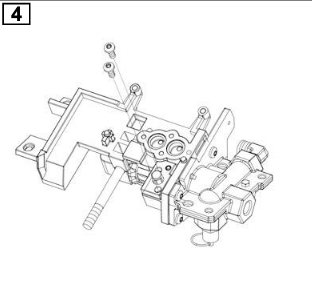

Replace the tank indicator parts with the new parts and re-install the screws. Torque to 8-10 LB-IN.

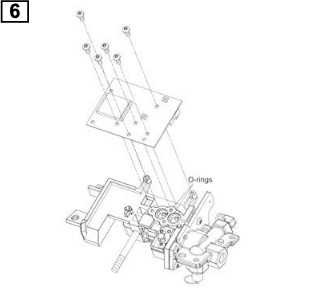

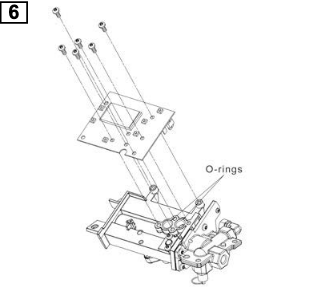

Install the control board and torque the 6 screws to 8-10 LB-IN. NOTE: Make sure the (2) o-rings are in position.

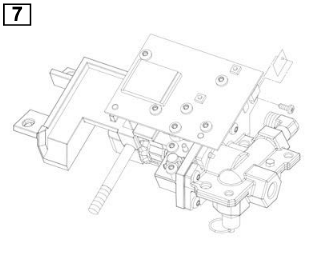

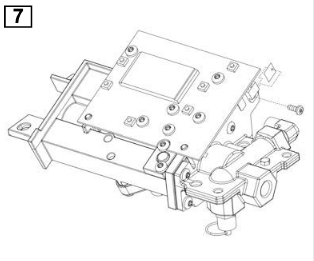

Position the sill pad between the triac on the control board and the manifold. Torque the traic screw to 8-10 LB-IN.

TANK PRESSURE INDICATOR KIT

165-0267 - Electronic regulator control

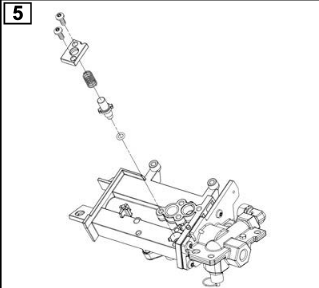

Remove 6 control board screws.

Remove triac screw.

Lift the control board from the manifold.

Remove the 2 screws from the tank indicator cap.

Replace the tank indicator parts with the new parts and re-install the screws. Torque to 8-10 LB-IN.

Install the control board and torque the 6 screws to 8-10 LB-IN. NOTE: Make sure the (2) o-rings are in position.

Position the sill pad between the triac on the control board and the manifold. Torque the traic screw to 8-10 LB-IN